I have most of the easier pieces cut for my chair. Now onto the more difficult and time consuming parts, the front and rear legs. The rear legs are similar to the Maloof design. The front legs are shaped and sculptured not turned. I prefer the sculptured front legs as they give the appearance of a chair hugging you. Once again, I'm using Sam Maloof's design with some changes. You can see closeups of these joints at,

mahoneywoodworks.com. It is hard sometimes to understand if you haven't built one of these chairs. I still have to refer back to my first chair from time to time.

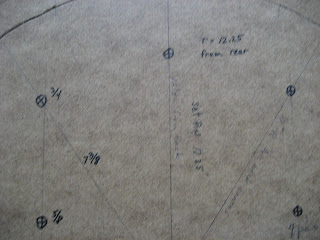

In this pic you can see my 1/4" mdf templates on the material. Don't worry about waste when making the legs. It's more important to get the grain running in line with the chair legs. You may have to angle the template on the material to achieve this. When I purchased the wood for this chair I spent time thinking through each piece so I already had this wood in mind for the legs. You will notice that I have the seat joint area on the rear legs flush with the edge of the board. I want a clean edge here to aid in making the leg to seat joint. I want a good edge also to work with the rear leg to arm joint. Both of these cuts are 90 degrees to the seat. When I have the rear leg attached to the seat you can see this relationship. It maybe hard to visualize now. The wood I choose is wide enough for two rear legs so after I make out the legs I will separate them on the band saw. Don't cut the shapes just yet. After the legs are separated I now have 2 legs ready for the dado joints. I want to make the leg to seat joint while I have a good, straight edge to work with. I will be setting up my table saw with a dado blade and saw sled. My dado blade is set to 3/4" wide and the depth of the dado is 1/4" deep. If you look at the seat joint previously written about you will see what I have to match.This pic shows the two legs clamped together after I marked out the dado. Notice the 5 degree angle. The rear legs will be splayed out 5 degrees. I always have to stop and take a second or third look at this joint angle and make sure I'm cutting the correct surface. The angled dado is facing the front of the chair. The straight dado or 90 degrees to the edge of the material will face the side of the seat.

I now separate the two legs and using the table saw sled cut the dadoes. I have a 5 degree tapered wood shim that I use up against the sled fence to maintain the correct degree. I will always clamp the piece to the sled when making cuts so I have no movement. This joint is a vocal point and closely looked at by most woodworkers. We are always checking out each others work. Before I actually cut the leg dado I will make a sample cut on some scrap material, using the digital caliper to verify the depth and width of the cut. I can use this sample piece to see if the dado will fit the seat cutout. The dado should be a snug dry fit. If it's sloppy it will show up in the end. I find the rear leg to be easier to fit as you are only working with two adjacent sides. The front legs are harder in that they have 3 sides to fit.

I will cut the front legs at the same time. I don't like changing blades so I want to make all the dadoes once. The procedure for the front legs is the same, mark out the pieces with the templates, keep the leg material square all 4 sides. I will use 8/4 material and add a 3/4 piece to what will be the outer edge of the leg. I now have legs that are 2 1/2" thick. The width of the leg needs to be sized to the total width of the seat cutout, which in this case is also 2 1/2". Look at the front seat notch, a 2" notch plus 1/4" rabbit on each side equals 2 1/2" total. This needs to be matched prior to making the dadoes. Once I have the width matched I will use the router table to make the round over on the two inside corners. You only have to round over 2-3 inches, don't round over any more as you need square edges to complete the rough shaping after the dado has been cut.

This pic shows the layout of the front legs prior to adding the 3/4" piece to the outside edge. You could cut the dado and then add the 3/4" piece. I like to add the piece first so that when I start the cutting I can continue with the rough bandsaw cutting of the profile. I make another sample piece that the same size width about 12" long and route the 1/2" round over. Check the fit to the seat. I find that some sanding of the rounded over corner will be required for that perfect fit. All these angles, round overs, dadoes and joints will be highly visible to take extra care. When I'm making these joints I think of how Sam Maloof demonstrates his techniques. Watching his videos you get the idea that it's easy. Well it was for him, but for me, I like the material clamped and the router stationary. I want to be able to play my guitar and piano when I'm finished.

Here I made the dadoes on the 3 edges. Next I will make the 1/2" round over on the 2 inside corners. Slide the legs over the seat joint and mark the correct corners. I say this as I once rounded the wrong ones. So now I double check. Take care with the router and sneak up on the dado area. You don't want any blowouts of the corner. Now I'm ready to cut the legs to length and bandsaw the front and side profile. The front legs appear to be short but keep in mind that I will adding a 2" thick block to the top. This block will be the transition piece to the bottom of the arm. It will be the width of the arm blank and about 6" - 8" long. After I bandsaw a profile on one face, I will save the cutoffs and tape them back on. This makes it easier to cut the other face profile. For these profiles I will use 1/8" mdf templates as they bend. You will lose your drawn profile for one side after the first cut so remarking is required.

This pic shows the added 3/4" piece on the outer side. I added this piece after making the dadoes. The leg has been band sawed on the front edge. I'll mark the side profile next and cut to shape. Be careful not to cut into the curved area that meets the dado. Leave it a little proud. After I have all the profiles cut, I will dry fit the legs to the seat and mark with a razor knife the top and bottom of the joints. I can then remove the legs, clamp them in my workbench vise and shape closely to these marks. The final shaping to the seat is after they are glued in. I want to get them as close a possible before glue up as this cuts down on the shaping and sanding to the seat. I find cherry to be harder to shape into the seat than walnut. The darker woods help any imperfections. Don't use this as an excuse for a poor joint. All the joints should be perfect. I spend most of my time on these pieces while in the dry fit stage. After I have all the profiles cut and sanded to shape I will round over the edges as much as I can staying away from any transitions.

This pic shows the small transition block at glue up to the arm. The arm has been rough shaped, the transition block has been attached to the top of the leg. I first attach the block to the leg using a long screw and epoxy. The block needs to be precut to the front shape of the arm as it will make shaping easier later. You will also notice the curve marks that I use to shape the leg to the underside of the transition block. The arm will be attached to the leg but the leg has not been glued to the seat. After the arm to leg assembly I can now shape the transition block to the arm on my workbench. It is much easier to shape before as you are only dealing with the arm and leg and not the whole chair.

Here you see a finish arm to leg piece and the other leg/arm in the rough. I skipped ahead abit as I need to show the arm process. The arms can be somewhat intimidating but I do enjoy making them. I'll cover the arms next.